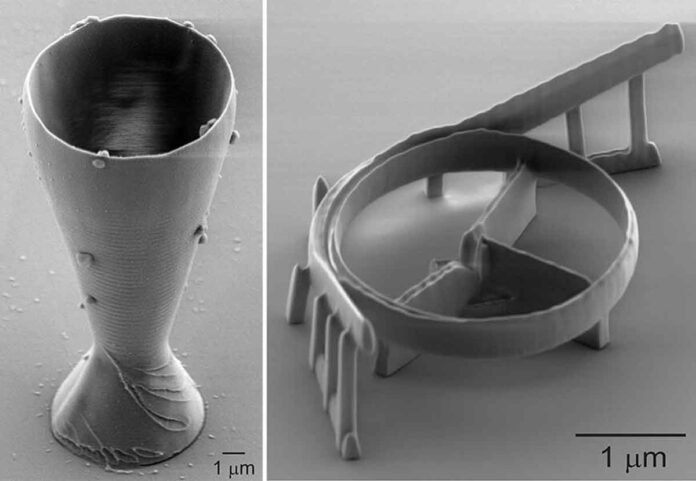

Researchers at the KTH Royal Institute of Technology in Stockholm have achieved a remarkable feat by 3D printing the world’s smallest wine glass.

This extraordinary creation boasts a rim even smaller than the width of a human hair, showcasing a groundbreaking technique for producing silica glass structures.

While the wine glass itself is a captivating demonstration, the true significance lies in the simplified method’s potential applications in various fields, ranging from telecommunications to robotics.

The team, led by Professor Frank Niklaus, encountered numerous challenges associated with 3D printing silica glass components.

One of the key obstacles was the requirement for thermal treatment.

However, the researchers successfully overcame this limitation, paving the way for the development of customized lenses for medical machinery, micro-robots for extreme environments, and filters and couplers for fiber optic networks.

In a study published in the journal Nature Communications, the scientists showcased the versatility of their technique by producing a fiber optic filter directly on the tip of an optical fiber as thin as a strand of human hair.

This breakthrough opens up a world of possibilities in the realm of optical communication.

"The backbone of the internet is based on optical fibers made of glass. In those systems, all kinds of filters and couplers are needed that can now be 3D printed by our technique," explains co-author Kristinn Gylfason, an associate professor of Micro- and Nanosystems at KTH. "This opens many new possibilities."

One of the remarkable advantages of this new method is its ability to drastically reduce the energy requirements for 3D printing silica glass.

Traditional methods involve heating materials to extreme temperatures for prolonged periods.

However, the researchers have eliminated the need for thermal treatment, allowing the glass to withstand high temperatures in practical applications.

Moreover, the newfound technique relies on readily available commercial materials, making it easily accessible for widespread adoption.

By eliminating the thermal treatment process, the potential uses for 3D glass printing expand significantly.

Potential Breakthrough for 3D Glass Printing

While further optimization is necessary for different applications, the team believes that their method represents a crucial breakthrough for the practical implementation of 3D glass printing.

With the elimination of thermal treatment and the use of widely available materials, the technique holds promise for various industries seeking innovative solutions.

As for the world’s smallest wine glass, its uniqueness lies not only in its size but also in its material.

According to Professor Niklaus, this glass is the first-ever 3D-printed wine glass composed entirely of glass.

Previous demonstrations primarily involved printing objects using different materials, such as statues and model cars.

This remarkable achievement in glass printing highlights the potential for creating complex and delicate structures using this advanced technique.

The researchers’ groundbreaking work has caught the attention of experts and industry professionals alike.

As they continue to refine their method, it is expected to revolutionize the production of silica glass components.

The ability to create tailored glass structures for various applications will unlock a new era of innovation and design possibilities.

The future implications of this breakthrough are vast, and the potential impact on industries such as medicine, telecommunications, and robotics cannot be overstated.

With the successful printing of the world’s smallest wine glass, the researchers have demonstrated the immense potential of 3D glass printing, leaving us eagerly anticipating the next wave of astonishing creations that will redefine what is possible.

FAQ

The 3D printing of the world’s smallest wine glass holds immense significance as it showcases a groundbreaking technique for producing silica glass structures. This achievement demonstrates the potential for creating intricate and delicate glass objects using advanced 3D printing methods. It opens up new possibilities for various industries, including telecommunications, robotics, and medicine.

Unlike previous demonstrations that utilized different materials for 3D printing, this technique stands out because it prints objects using glass. The world’s smallest wine glass is the first-ever 3D-printed glass wine glass. This distinction highlights the ability to print complex glass structures and paves the way for further advancements in glass printing technology.

The applications of this 3D printing technique are extensive. It enables the production of customized lenses for medical machinery used in minimally invasive surgeries. Additionally, it facilitates the creation of micro-robots capable of navigating extreme environments. The technique also allows for the printing of filters and couplers for fiber optic networks, which are crucial components in the telecommunications industry.

The newly developed technique overcomes the need for thermal treatment, a previously necessary step in 3D printing silica glass components. Traditional methods involved heating materials to high temperatures for extended periods. By eliminating the requirement for thermal treatment, this technique reduces the energy needed for 3D printing and enables the glass to withstand extreme heat in practical applications.

One of the advantages of this technique is that it can utilize readily available commercial materials. By using commonly accessible resources, the process becomes more practical and cost-effective. This aspect increases the potential for widespread adoption of 3D glass printing in various industries.

Yes, while the current method shows great promise, further optimization is required for different applications. Each application may have specific requirements and considerations that need to be addressed. However, the researchers believe that their technique represents an essential breakthrough for 3D glass printing and serves as a crucial step towards its practical implementation in diverse scenarios.

The future implications of this breakthrough are vast. The ability to 3D print glass structures opens up new possibilities for design, manufacturing, and innovation. It has the potential to revolutionize industries such as medicine, telecommunications, and robotics. By enabling the creation of customized glass components, this technique will drive advancements in various fields, leading to improved technologies and novel applications.

More information: Nature Communications (2023). DOI: 10.1038/s41467-023-38996-3