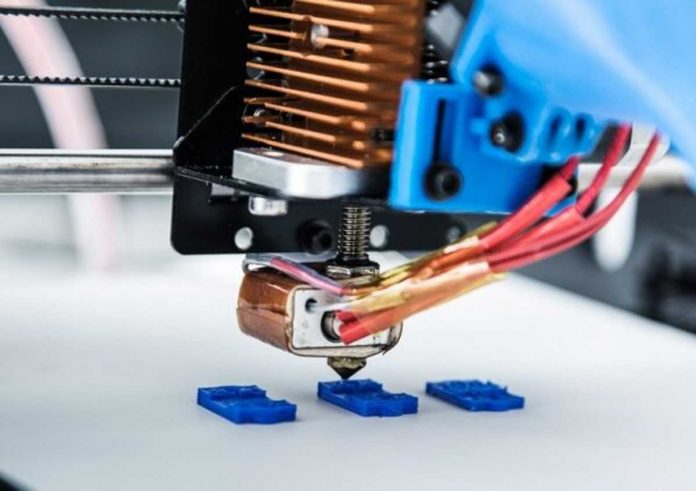

UNSW engineers have developed a way to help 3D printed plastic heal itself by using only lights in room temperature. UNSW School of Chemical Engineering professor Cyrille Boyer and his team that included Dr. Nathaniel Corrigan and Mr Michael Zhang showed us that adding “special powder” to the liquid resin of the printing process can later help in making quick and easy repairs if the material breaks.

This can be simply done by shining standard LED lights on the printed plastic for nearly an hour to cause a chemical reaction and fusion of the broken pieces.

The process makes the repaired plastic stronger than it was before the damage happened. Scientists hope that further development and commercialisation of this process will help in reducing chemical waste in future.

The broken pieces of plastic would not be thrown away or recycled. It will be simply mended by remaining embedded in a component with other materials.

This research paper has been published in the journal Angewandte Chemie International Edition.

It will reduce plastic waste

Dr. Corrigan said “There is an obvious environmental benefit because you’re not having to re-synthesize a brand-new material every time it gets broken. We are increasing the lifespan of these materials, which is going to reduce plastic waste.”

In places where we use polymer material, we can use this technology. After a component fails, we can repair the material instead of throwing it away.

The UNSW team has used a powdered additive which is a trithiocarbonate, known as a reversible addition fragmentation chain transfer or RAFT agent. This is originally developed by CSIRO. The agent enables the rearrangement of the nanoscopic network of elements which make up the material and fuse the broken pieces.

The process takes approximately 30 minutes when UV LED light is directly pointed onto the broken plastic. The plastic is fully healed after roughly one hour.

Scientists have experimented with a 3D printed violin. This experiment shows that self-repaired plastic’s strength is fully recovered as it was in its unbroken state.

The team of the scientists said commercialisation of the process is possible as the simplification and speed of their system is much higher than any other existing ways of repairing broken 3D printed materials.

Scientists said there are other process to heal these materials but they all are relied on thermal chemistry to repair it and that also takes nearly 24 hours. These processes also take multiple heating cycles to have the same result.

Dr. Corrigan said “Another restriction to that is that you need an oven which is heated to high temperature and you obviously cannot repair the plastic material in situ—you would need to disassemble it from the component first which adds a level of complexity and delay.”

With the new process, we can leave the broken plastic anywhere and shine the light on the entire component. This process is easy and faster as the additives at the surface of the material are only affected.

Scientists said we can use this process in a range of applications as 3D printed materials are now hugely used in high-tech specialized components. This includes wearable electronics, sensors and shoe manufacturing.