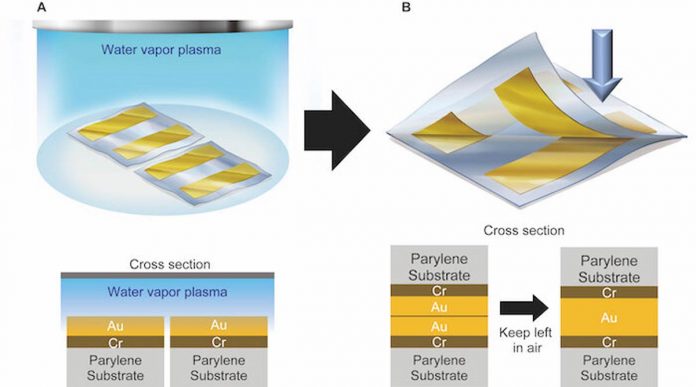

RIKEN Centre for Emergent Matter Science and RIKEN Cluster for Pioneering Research scientists have developed a new technique for improving the flexibility of ultra-thin electronics. The research paper has been published in Science Advances. The research paper has detail description of the use of water vapor plasma and how this can help in bonding gold electrodes. These electrodes have been fixed on a separate ultra-thin polymer film. This process will not need adhesives temperatures.

Electronic devices are become smaller day by day. With this the demand of bendable and on-skin electronics are also increasing. The conventional method of making these electronics have become outdated. One of the biggest problems in the old methods was to connect multiple devices of a device.

Conventional methods have used layers of adhesive to merge electrodes together. This needed temperature and pressure but that had damaged the super-thin electronics. Direct metal-to-metal bonding isa available in conventional method. That would also need smooth and clean surfaces which is not there in electronics.

Researchers have developed a new method. This method does not need high temperature and pressure. This method also does not require smooth or clean surfaces. The new method takes only a minute at room temperature to complete its functions. We need to wait for 12 hours to get the final result. The new method is called water-vapor plasma-assisted bonding. The method creates a stable bonding between gold electrodes which is printed in ultra-thin polymer.