The University of Tokyo researchers discovered that cyclic material fatigue can begin to fracture amorphous materials at the same stress level as fractures caused by constant loading. The team was able to distinguish four distinct failure modes using computer simulations. This research could extend the life of industrial machinery.

Damage to industrial parts is costly, causes delays, and may endanger plant workers. However, Japanese scientists have now simulated fracture initiated in materials that share a specific physical property and are widely used in domestic, industrial, and scientific applications. Their research, published in Communications Materials, yielded unexpected results that could aid in the prevention of industrial part damage.

If you’ve ever been bored in a meeting and tried passing the time by playing with a metal paperclip, you may have noticed something surprising. Although the paperclip begins flexible and returns to its original shape several times, it may snap after a certain number of cycles. This is an example of “fatigue,” which occurs when an object is subjected to cyclic loading and unloading of stress. Material fatigue is a major concern in many industrial applications, particularly for machine or aeroplane parts that go through many cycles of stress and where a sudden failure could be disastrous. As a result, gaining a better understanding of the underlying process of material fatigue could have significant implications, particularly for non-crystalline materials.

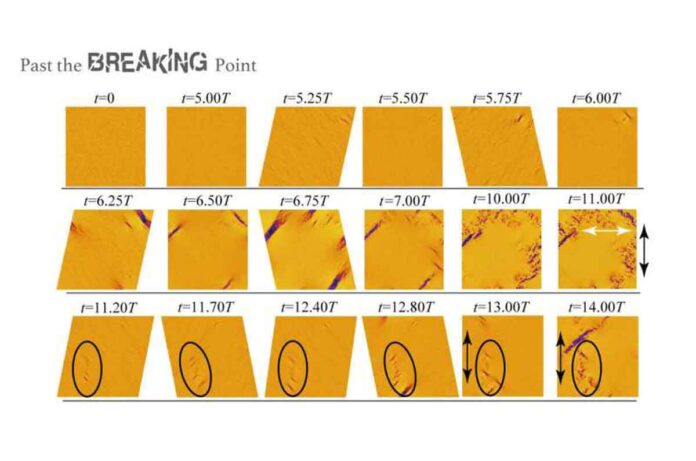

Using computer simulations, a team of researchers from The University of Tokyo’s Institute of Industrial Science investigated the physical mechanisms of low-cycle fatigue fracture in amorphous solids such as glass or plastics. It has been demonstrated that pre-existing defects and grain boundaries in crystalline materials can cause a fatigue fracture.

The corresponding mechanism in amorphous materials, on the other hand, is poorly understood. While it may appear intuitive that the stress required for a fracture is much lower for cyclic stresses compared to constant stresses, this was not the case.”We demonstrated that the critical strain in disorder materials that correspond with the onset of irreversible deformation is the same for both fatigue and monotonic fractures, contrary to popular belief,” says co-author Yuji Kurotani.

This is because higher density causes more elasticity and slower dynamics in ordinary amorphous systems. The density dependence of mechanical properties links shear deformation to density fluctuations. The cyclic shear can then amplify density fluctuations until the sample breaks through cavitation, resulting in voids.

“This is like being on a crowded train,” says co-author Hajime Tanaka. “In terms of density changes, dynamic and elastic asymmetries can lead to a link between shear deformation and density fluctuations.” These authors state that these findings should be confirmed through experiments, which would also help material scientists better understand fracture initiation.