Rice University scientists found a possible to get and recycle rare earth elements. Scientists reported they have successfully extracted valuable rare earth elements from waste. It yields high to resolve issues for manufacturers while boosting their profits.

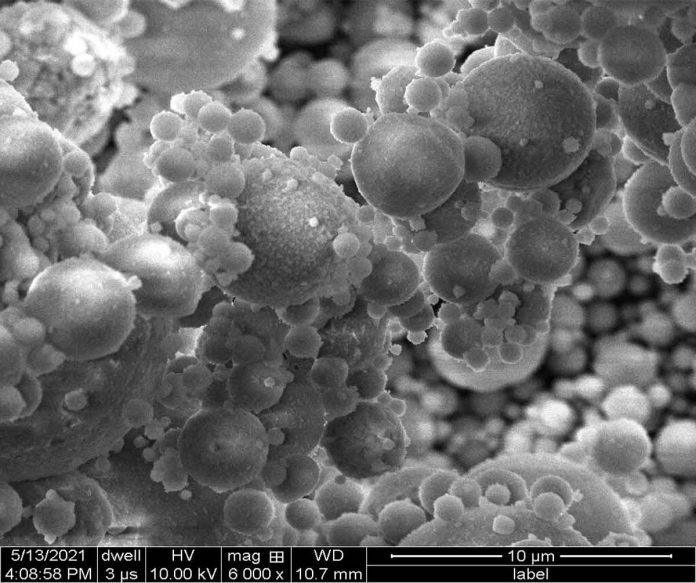

Scientists used flash Joule heating process. It was introduced several years ago to produce graphene from any solid carbon source. It has now been applied to three sources of rare earth elements such as coal fly ash, bauxite residue and electronic waste. This recovers rare earth metals. This have magnetic and electronic properties which are critical to modern electronics and green technologies.

The process is kinder to the environment. It uses less energy and turns the stream of acid often used to recover the elements into a trickle. The study has been published in Science Advances.

Rare earth elements aren’t rare. Cerium is more abundant than copper. But these 15 lanthanide elements are widely distributed. These are also difficult to extract from mined materials.

There is plenty of incentive to recycle what’s been mined. Much of that is piled up or buried in fly ash. These are byproduct of coal-fired power plants. Bauxite residue is also called red mud, is the toxic byproduct of aluminum production.

Industrial extraction from these wastes involves leaching with strong acid. It is a time-consuming and non-green process. Scientists heated fly ash and other materials to about 3,000 degrees Celsius in a second. This process turns the waste into “activated REE species.”

Industrial processes use a 15-molar concentration of nitric acid to extract the materials. Here scientists used milder 0.1-molar concentration of hydrochloric acid that yields more product.

Scientists found flash Joule heating coal fly ash more than doubled the yield of most of the rare earth elements. They used very mild acid compared to leaching untreated CFA in strong acids. The generality of the process made it promising. Millions of tons of bauxite residue and electronic waste are also produced every year.